Whether you know a lot or very little about used tires, it’s important to understand what misconceptions are out there about this issue and the methods for cleaning up scrap tires. Here are some answers to the questions we most often hear about used tires, and tire-derived fuel specifically, that will help you gain a clearer understanding of this important issue.

Frequently Asked Questions

How many tires end up in landfills?

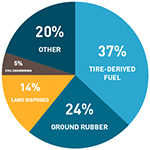

According to the U.S. Tire Manufacturers Association, about 14 percent of used tires in 2019 ended up being land disposed, meaning they went to landfills or monofills (tire-only landfills). This percentage amounts to about 41.5 million tires that could have been reused or recycled. Used tires that don’t end up being land disposed are most often used for tire-derived fuel, ground rubber or civil engineering projects, among other uses.

What about used tires that end up in piles and not in a landfill – how many of those exist?

Tires that end up in piles outside of a landfill are known as “tire stockpiles.” In 1990, there were around one billion scrap tires in stockpiles across the U.S. Although more than 94 percent of these have been cleaned up since then, around 56 million stockpiled tires still remain. Many states are working to clean up these stockpiles, but some have a long way to go. The majority of stockpiled tires are in these eight states: Arizona, Colorado, Michigan, New Jersey, New Mexico, Texas, Virginia and Washington.

What are the negative impacts of scrap tires?

Many used tires are often unsafe for everyday use due to flaws or age. If these tires aren’t recycled or reused in a safe way, they can find their way back to the road – a potentially dangerous scenario. When these tires are brought to landfills, they take up valuable space from materials that can’t be recycled like a tire can. Landfills need to be reserved for materials that have no other options. Once in a landfill, though, tires can take hundreds of years to decompose. These landfill sites, along with stockpiles, also pose environmental and health risks due to the materials they are made of. They can become ideal breeding sites for mosquitoes that carry diseases and can be a catalyst for fires that are hard to extinguish and can pollute the air, soil and water.

What are the different ways tires can be reused and recycled?

There are a variety of uses for scrap tires that the Federal Environmental Protection Agency deems as viable methods along with traditional recycling. Some of the ways we can re-use and recycle used tires include:

- Building DIY planters, tire swings or crash barriers on race tracks.

- Recycling tires into rubber products, mulch for athletic fields, or into material for rooftops and pathways.

- Creating an alternative energy source known as tire-derived fuel.

In fact, scrap tires are most often used for tire-derived fuel, ground rubber or civil engineering projects, while around 14 percent of them end up being disposed.

What is tire-derived fuel (TDF)?

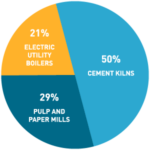

The use of TDF in the manufacturing industry is one of the largest – and oldest – markets in the U.S. for scrap tires. Many factories use this environmentally-sound alternative energy source that can turn tires into fuel due to their high heat value. In 2019, out of the 263.4 million used tires generated, 101 million were diverted from landfills and used as TDF. Industries like the ones listed here use this fuel most often.

The use of TDF in the manufacturing industry is one of the largest – and oldest – markets in the U.S. for scrap tires. Many factories use this environmentally-sound alternative energy source that can turn tires into fuel due to their high heat value. In 2019, out of the 263.4 million used tires generated, 101 million were diverted from landfills and used as TDF. Industries like the ones listed here use this fuel most often.

What are the benefits of TDF?

In 2019, 263.4 million scrap tires were generated across the United States. Around 101 million of these were used as TDF, keeping them out of landfills and off the road. Over the last 15 years, LafargeHolcim alone has redirected more than 100 million tires from landfills by using this process at some of its cement plants. Additionally, using TDF can help lower carbon dioxide, nitrogen and sulfur emissions while producing the same or more energy as other fuels.

Is TDF safe?

TDF has also been used for around 30 years and is a proven and safe technology. This technology is regulated by most state environmental protection agencies that help ensure this proven technology is used correctly. TDF, along with other viable options for used tire reuse and recycling, save hundreds of millions of tires from landfills every year through safe and environmentally responsible means.

Does using TDF impact the environment?

When used properly, TDF does not impact the environment. It is safe and widely recognized, including by the Federal Environmental Protection Agency, as a viable option for reducing tires in landfills and stockpiles. When creating TDF, tires are placed in a kiln with very high temperatures that stay above at least 1000°C for a long period of time and reach up to 2000°C. This high heat guarantees the tires are fully disintegrated; meaning, there is nothing left behind of the tires that needs to be landfilled or that will go into the air.

But if you burn tires, won’t that put smoke and tire pieces into the air we breathe?

The quick and complete disintegration of tires through TDF keeps particles out of the air. Tires have a high heat value, so the process for creating TDF uses very high temperatures that fully incorporate the tire’s mineral components into the new product, leaving nothing behind.

How is TDF regulated?

Day-to-day management of the collection of scrap tires is regulated at the state level. In 1985, Minnesota enacted the first state law for the management of scrap tires. Currently, 48 states have enacted laws or regulations that address scrap tire management. These regulations are most often carried out by teams trained in handling TDF procedures. Facilities must generally have a tire storage and handling plan; secure a permit for all applicable state and federal environmental programs; and remain in compliance with all permit requirements.

What is the process of making energy from tires?

First, used tires are gathered by trucks and other means to be used as fuel. Both whole tires and scraps are viable options for manufacturers like cement plants, pulp and paper mills, and electric utility boilers to use for energy. After arriving at a plant, tires are first shredded or used whole and fed into a kiln on a conveyer belt. Temperatures up to 2000°C ensure the tires are quickly and completely disintegrated. The energy is then recovered within the kiln, creating fuel to power the kiln or the plant.

How does the use of TDF compare to other energy sources?

Using TDF as an energy source can produce lower emissions of carbon dioxide, sulfur and nitrogen while producing the same or more energy as other sources.